Here’s a repair I did on a water damaged popcorn ceiling at a condominum complex that I have the contract to do all of their drywall and painting work in Cape Canaveral, FL. The water damage was caused by a roof leak during Tropical Storm Debby.

Water Damaged Popcorn Ceiling:

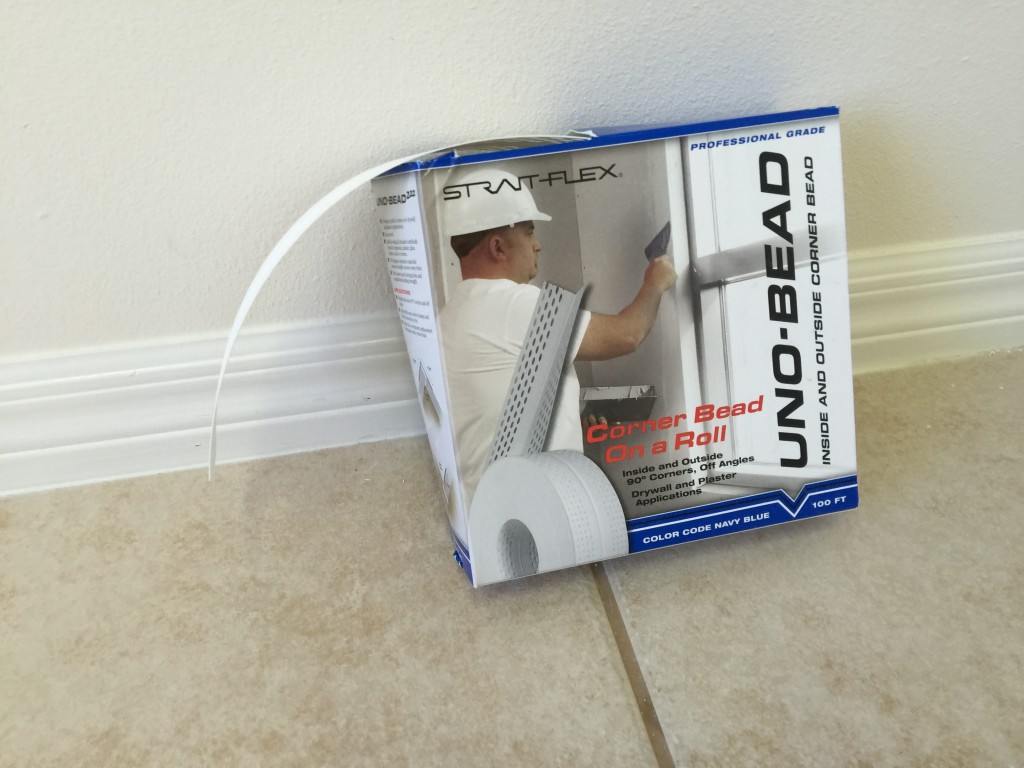

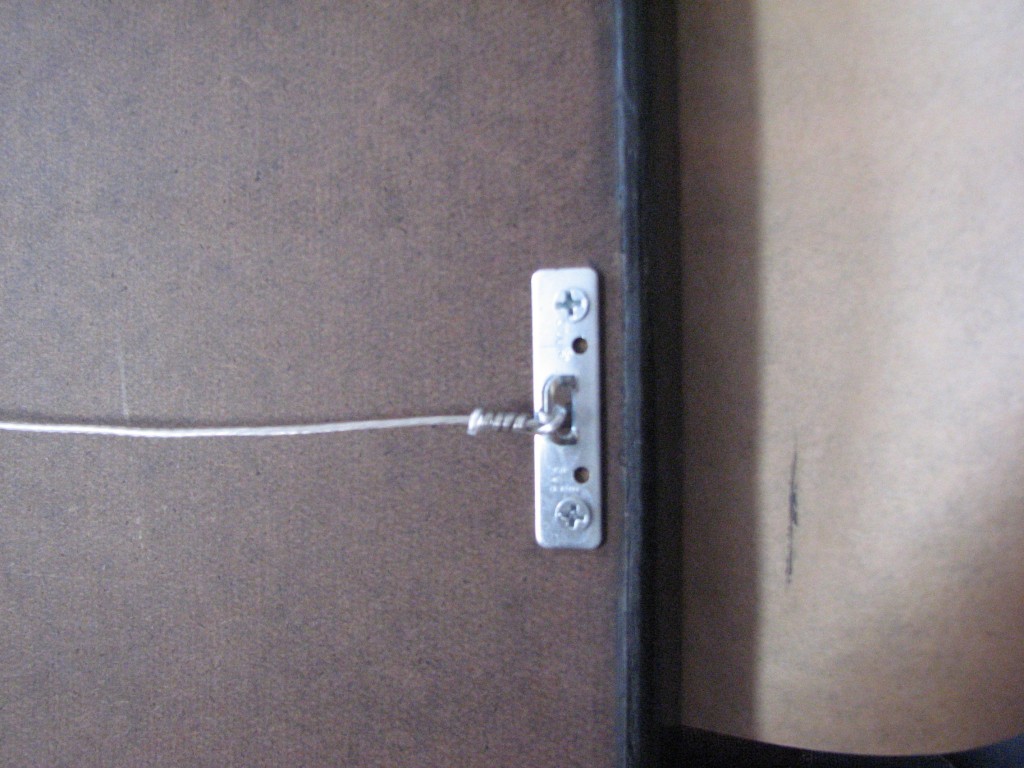

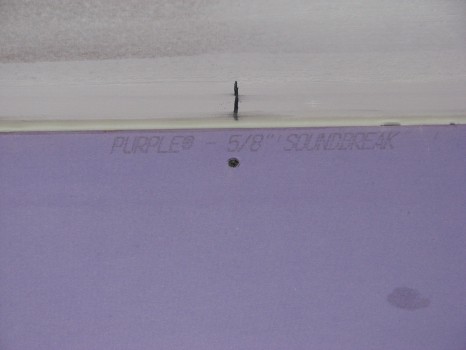

Water damaged area cut out and new drywall installed.

Ceiling repair taped, mudded and skim coated.

New popcorn texture applied and feathered out to blend into existing popcorn texture on the ceiling.

Water Damage Specialist’s

Please feel free to call or Email us for more information about our Interior and Exterior Painting services!

Or simply just

Click to schedule an Estimate Here

Brevard County Painting License #PT393

State License # RX11066969

Please give us a call for a prompt and accurate quote for allyour popcorn ceiling repair needs!

South: 321-777-9337

Central: 321-453-6233

Mel B.- Merritt Island, Fl

Mel B.- Merritt Island, Fl